MARK X

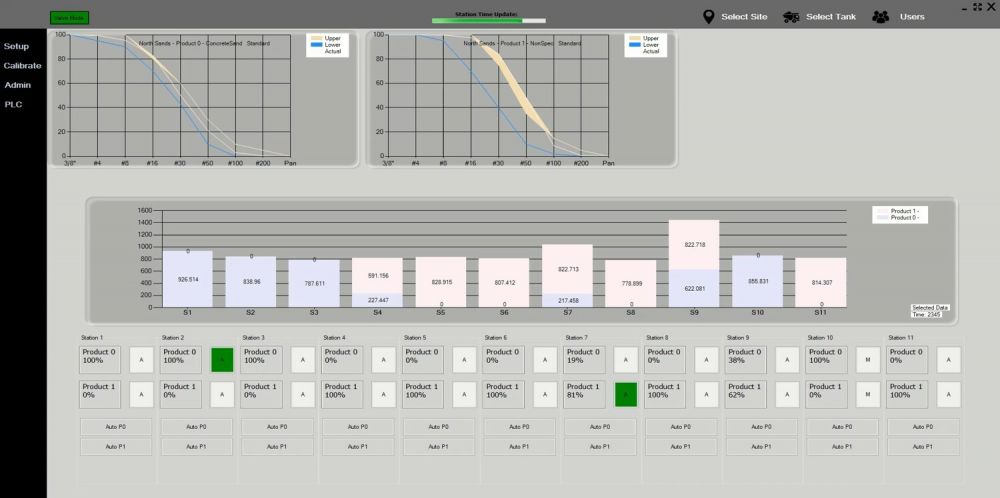

Eagle Iron Works’ Mark X, powered by Inspec® Sand Software, is the ultimate in sand reblending systems. It does all the thinking to keep your product within the specification, even when the feed changes. It has been designed and tested by a team of software engineers who understand your needs to help you maximize your productivity.

Mark X provides a fully automated method to optimize sand production. You tell the computer what function is most important to you, and it performs the complex calculations necessary to achieve the desired results. By continually monitoring the tank’s activity and automatically adjusting the station percentages accordingly, tight tolerances for typical construction sand specifications are maintained.

Featuring enhanced tank configuration, Eagle’s Mark X can run single or multiple tanks with seven to 11 stations per tank and two to three valves per station. It features a touchscreen interface offering intuitive commands and providing all needed information available at the ready. Real-time valve status indicators offer a look at what is happening inside the tank. When the valves are ready to release the material, simply tap on the valve on the screen to open it. Mark X offers automatic and manual percentage adjustments to adapt to changing feeds, and with stockpile calibration, the Mark X improves accuracy and simplifies the calibration process.

Mark X Features:

- Multiple feed locations

- Multiple site configurations

- Adapts to changing feed

- Hydraulic pressure/level and specific gravity sensors offered as optional features

- Modern graphical user interface

- Intuitive dropdown menus for site, tank and product configuration

- Features PLC diagnostics page to simplify system troubleshooting

- Visualize real-time production data and station activity

- Centralized calibration tools

- Automatic and manual valve control

The EIW Advantage

Eagle Iron Works’ Mark X offers many advantages over competing systems, including:

- Predictive controls instead of batching or timing

- Backwards compatibility

- Remote operation

- Remote support

- Report generation

Digital DIALSPLIT

The Digital DIALSPLIT is the most basic of Eagle Iron Works Sand reblending control options. The primary advantage of this system is that it eliminates the time consuming job of manually adjusting splitter gates on Classifying Tank valves, as well as provides calibrated settings. It is good for feeds that have constant gradations and tonnages because if the feed changes. It allows for percentage-type settings and can save up to 12 recipes.

Each setting station on a tank equipped with DIALSPLIT controls has two, three, or four discharge valves that release material into separate cells of a collecting-blending flume. The valves discharge only after enough sand has accumulated to reach a sensing paddle. When this occurs, the DIALSPLIT control panel determines which valve at that station will open. The dial settings on the DIALSPLIT are determined by the percent of pit gradation required to meet product specifications. Once set, the system will continue to dispense material in the same proportion.

The control is easy to understand and operate. The number of switches per station on the control corresponds to the number of cells in the settling tank: one switch for a 2-cell tank; two switches for a 3-cell tank; and three switches for a 4-cell. Each cell is capable of producing a controlled product, with one cell yielding a residual product. For example, a 3-cell tank would yield two controlled products, as well as a residual product.

Eagle Water Scalping-Classifying Tanks equipped with DIALSPLIT controls are completely wired and have multiple valves at each discharge station.