Eagle Iron Works’ Pug Mill Mixers, sometimes known as Stabilized Base Mixers, are high-capacity continuous mixers for applications in many industries.

There are many applicable uses for Pug Mill mixers. This includes as cold-mix asphalt trains and hot-mix asphalt plants; preparing stabilized base materials for roads and highways; and mixing reagents with contaminated earth in soil remediation projects. With small modifications, these machines even work in power generation plants to pug neutralizing agents into flue gas desulfurization byproducts.

Pug Mill Mixers have a sturdy box construction, featuring a rectangular feed inlet with optional hopper on top and a rectangular bottom discharge opening at the opposite end. Hinged inspection ports on the top of the machine open to expose the expanded metal personnel safety covers underneath.

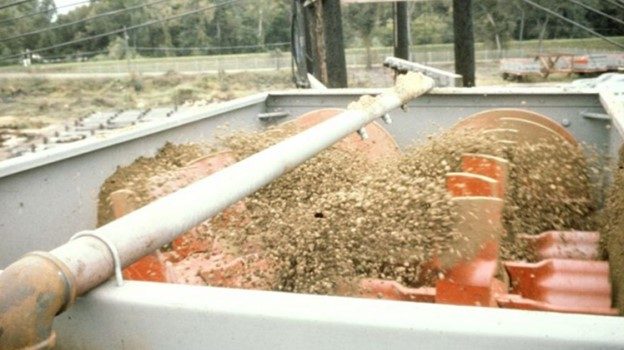

Available spray bars and a direct reading flow meter make it easy to control the product’s moisture content if required. Plumbing can be modified to accommodate bituminous emulsions or other viscous fluids. The counter-rotating twin shafts have intermeshing paddles cast of abrasion-resistant Eagle Armor, a chromium-nickel iron alloy. The Pug Mill Mixer’s shafts are synchronized and supported at one end by a single-input, double-output speed reducer of Eagle Iron Works’ design, and are supported at the other end by flange mounted, grease lubricated roller bearings.

How Pug Mill Mixers Works

Solid materials should uniformly enter Pug Mill Mixers through the feed entry point. Materials are advanced through the length of the machine through paddles positioned at an angle on the shaft, during which the necessary blending action occurs. If required, spray bars with nozzles can be added either in the feed cute or above shafts immediately after the material enters the mixer box.

Product Features

Eagle Gear Reducer

- Designed and built at Eagle facilities

- Heavy-duty design with heat-treated helical gears

- 100% of the shaft’s thrust load carried by the output shafts

- Oil bath lubrication for maintenance-free operation

- Drive guards standard equipment

Mixer Shafts

- Intermeshing shafts provide thorough mixing of multiple materials

- High-grade, one-piece, thick-walled steel tubing

- Paddle mounting spuds and flanged ends submerged arc welded

Mixing Paddles

- Replaceable Eagle Armor paddles, 600 Brinell hardness

- Corrugated face for improved mixing capabilities

- Three-bolt fastening system provides solid connection to mounting spuds

- Reversible paddles to retard material flow for increased mixing action

Mixer Tub

- Fabricated with thick gauge steel

- Hinged safety covers

- Rectangular feed hopper

- Spherical-roller rear grease bearings

- Flow meter and spray bars for product moisture control if required by the application

Optional Equipment

- Curved close-clearance liners for processing binding materials

- Modular support structures

- Surge bins with hydraulically-operated clam gates

- Electrical control systems

- Pillow block rear bearings